Disclaimer not yet officially published and will be updated frequently!

I wanted to be able to make my own prototype PCB’s and was consider many different methods.

My conclution is that part from the not so nice to handle liquids that is nessesary to use the photoresist and etching method is by far the best and fastest for a home shop. This is tep one in a small series that will cover the tools and methods that I have ben choosen. Hopefully I will also build a PCB drilling CNC ;)

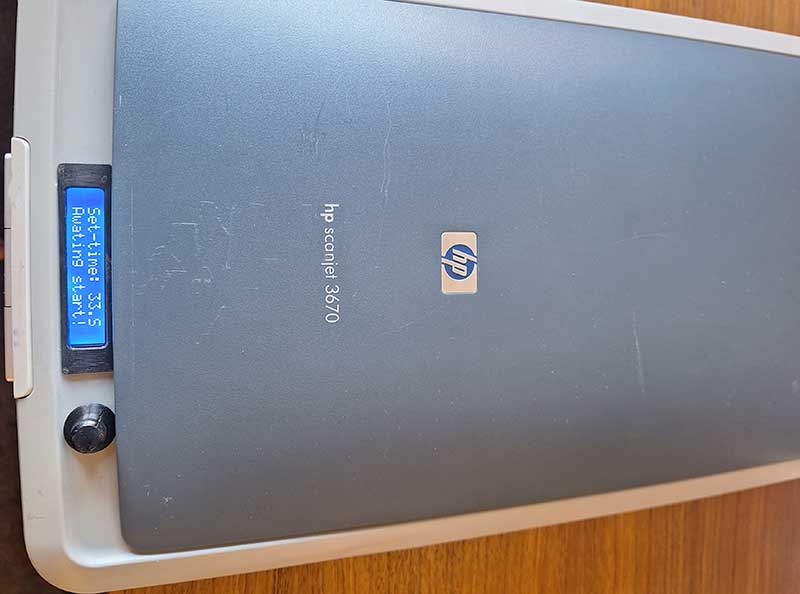

The victim to become transformation to UV exposure box a HP Scanjet 3670 bought for 20 euro’s.

It has been striped for all its internals I just keept the frot push buttons and two of them are used for start/stop of timer. It hade a space at the front top where I was able to cut a hole ad squeeze in the LCD.

I 3D printed a bezel for the LCD as my cutting wasn’t to pretty , and the potento meter knob was also printed files included att the bottom ;)

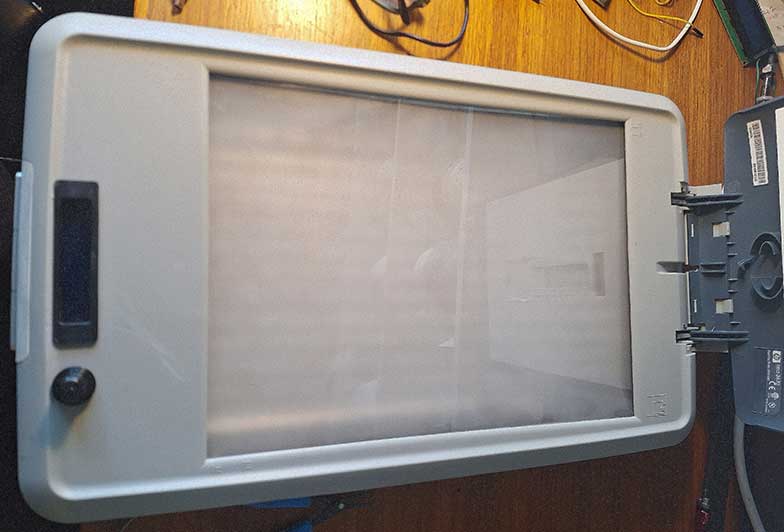

A pic showing the diffusion film being taped under side of and arround the edges of the scanner glass surface. The LED strip was first mounted on a white cardboard that was mounted with hot glue to the botom of the emty scanner casing. I was cutting the whole 5 meter UV light strip in short lengths and then soldered jumper wites between them. Later I found a much better and easier method, simply folding the strip!

surface. The LED strip was first mounted on a white cardboard that was mounted with hot glue to the botom of the emty scanner casing. I was cutting the whole 5 meter UV light strip in short lengths and then soldered jumper wites between them. Later I found a much better and easier method, simply folding the strip!

Hardware and build for PCB UV exposure box.

Old flatbed scanner (Pick one with enough space for LCD, PCB boards and Potentiometer BOM below.

BOM: LED+BOX MOD

UV Led strip 5 meter.

White hard or cardboard.

Diffusion gel film.

The timer circuit and code.

No flickering solution is based on this code: devxplained.eu/en/blog/using-lcds

Timer code partly borrowed from: robojax.com

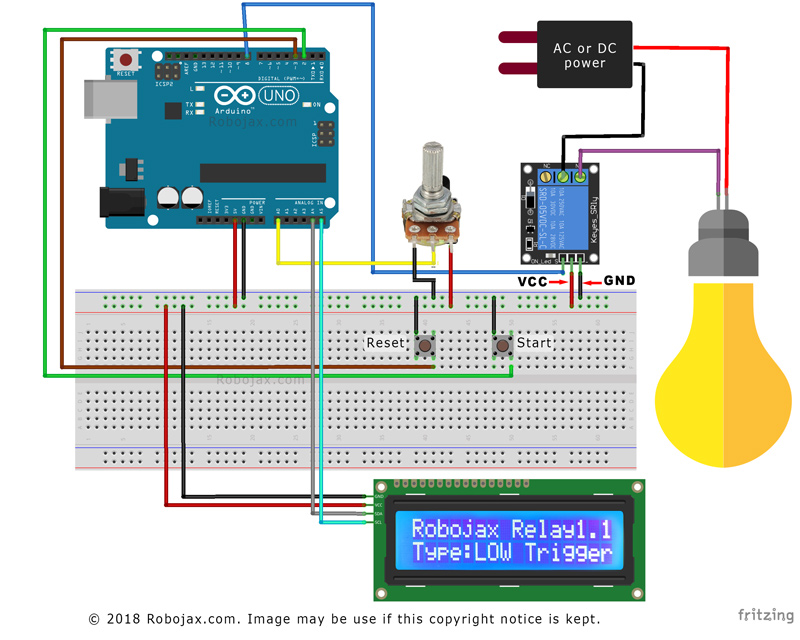

Schematics also by robojax.com my PCB does however carry all components exept LCD potentometer and buttons this will make it more easy to place the parts inside the scanner itself ther for I also used a Arduino Nano instead of UNO .

Schematic fritzing style!

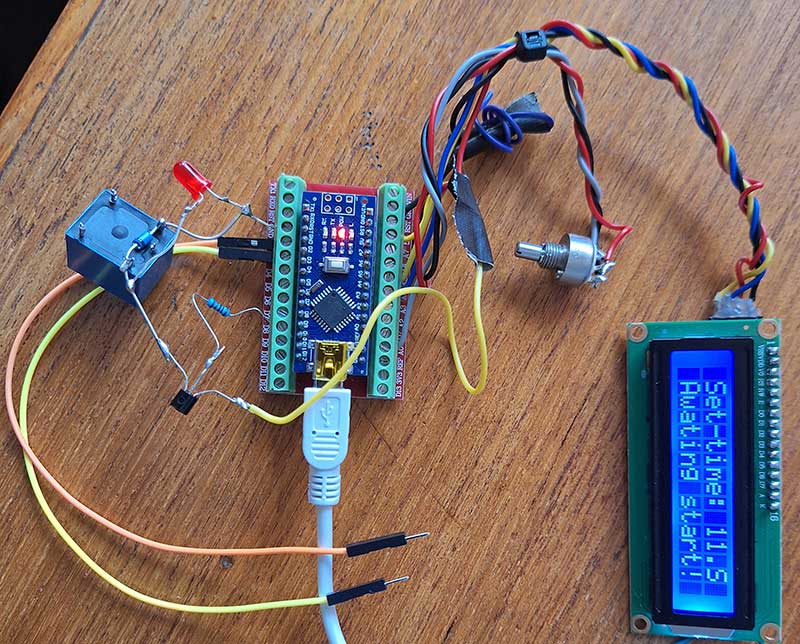

And my rats nest for testing. The UV box that I’m using right now has this circuit and is point to point wired with soldered jumpers, everything held in place by some fancy hot glue haha….

Display and arduino +relay is also powered with the same 12V power supply that are used for the UV led strips by the use of a 12v-5v DC-DC buck converter.

- BOM: TIMER ELECTRONICS

- 10K Multi turn poteniometer

- Arduino nano

- Relay board or relay + transistor

- Display HD44780 i2c

- 12V to 5V DCDC converter

- Wires, soldering equipment + time and patience

The full code for UV exposure timer used in Arduino IDE (zip download near bottom of this page)

Notes

If you don’t have a multi turn potentiometer on hand but still like fine controll of time settings, you can use two potentiometers in series like in the original set up se more here: robojax.com relay_timer_1.1

Files to download (to be added)

stl’s for bezel an knob + box for freestanding timer.

PCB files

More images